November 2023 | Volume 25 No. 1

Labelled with Diamonds

Listen to this article:

Counterfeiters grow smarter and use ever more sophisticated technologies each year, producing a huge variety of fake goods – from medicines through electronics to fashion – and causing health risks and the loss of billions of dollars worldwide. To fight back, the anti-counterfeiters are also upping their game.

Taking the sophisticated technology to the next level, a team from the Department of Electrical and Electronic Engineering have collaborated with counterparts in different fields of expertise to create innovative high-security labels which are impossible to replicate.

Research team leader Dr Zhiqin Chu said he hopes the significance of incorporating such advanced materials as diamond microparticles – which are ideal for their ‘chaotic’, and therefore unclonable, properties – will focus interest on this research field and inspire more innovations in anti-counterfeiting technologies.

“We made the labels by planting tiny artificial diamonds, known as diamond microparticles, on a silicon plate using a method called chemical vapour deposition (CVD),” said Dr Chu.

Unique, unclonable pattern

“Because the diamond microparticles are all different shapes and sizes, when scattered on the silicon substrate, they settle in a unique pattern each time, thereby creating the equivalent of a fingerprint for each label which is impossible to copy. In the anti-counterfeiting industry, this phenomenon is known as PUFs, or Physically Unclonable Functions.”

Additionally, the research team exploited the distinctive characteristics of diamond microparticles containing silicon-vacancy (SiV) centres, a kind of photoluminescent defect centre in the diamond lattice that has attracted much attention in various fields due to its unique optical and spectral properties. It can emit bright near-infrared photoluminescence when excited by green light, reducing the difficulty of distinguishing confidential from disturbance information.

According to Dr Chu, the inspiration that led the team to develop the security labels was actually the concept of PUFs itself. “PUFs are physical systems that produce unpredictable and irreproducible outputs,” he explained. “We realised that diamond microparticles have some particular advantages for PUFs, such as the inherently randomised features of each particle plus their high stability, biocompatibility, and optical properties. By incorporating them into security labels, we aimed to create an unparalleled level of security and authenticity verification.”

The team’s previous work includes the use of diamond-based colour space-correlated Raman spectroscopy for multilevel optical anti-counterfeiting and linear polarisation modulation of nanodiamonds for high-dimensional anti-counterfeiting. It was while working on the fabrication of high-quality diamond microparticles, that they found the diamond particles contain SiV centres with superior properties, enabling a wide range of practical applications.

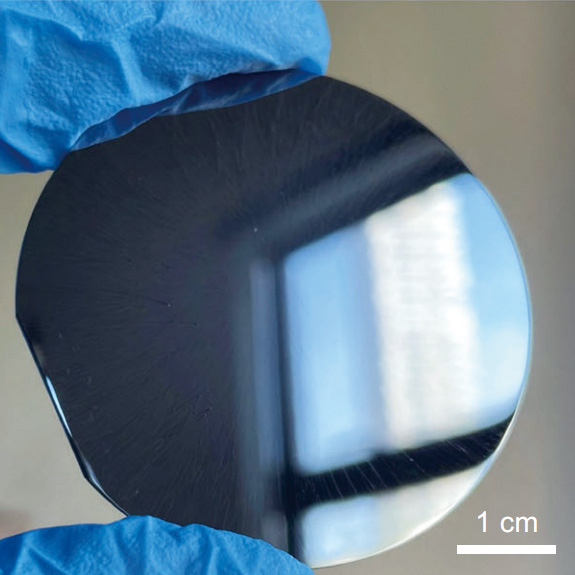

A two-inch diamond Physically Unclonable Functions label under natural light.

Collaborative efforts

The development of the novel security labels is the result of a collaborative research effort between HKU, Sun Yat-sen University and Peking University. The HKU team focussed on studying the properties of diamond microparticles, designing and implementing the idea of using them for anti-counterfeiting, understanding their behaviour when incorporated into the security labels, and optimising their performance.

The Sun Yat-sen University team contributed to the theoretical analysis and simulation of the optical scattering of the diamond microparticles; and the team at Peking University provided the expertise and facilities for the CVD process of growing the diamond microparticles.

While they have been used in various industries already for their exceptional properties, the application of diamond microparticles (heterogeneously grown by CVD on Si substrate) specifically for anti-counterfeiting purposes is unique to this team.

“There has been significant interest from various industries regarding the potential of these security labels,” said Dr Chu, “including from industry partners who are interested in using them in product labels such as luxury goods, pharmaceuticals, high-end electronics, and valuable documents.”

Further advantages are that the labels are cheap to produce (about US$1 to make 10,000), physically robust and able to withstand heat and chemicals. “Diamonds possess characteristics such as high hardness, chemical inertness, thermal stability, and unique optical features that make them ideal for practical anti-counterfeiting applications. For example, the hardness of diamonds ensures their durability and resistance to wear, making them difficult to tamper with or replicate,” said Dr Chu.

Currently, the team are finessing the research and development process, conducting extensive testing and validation of the diamond-based security labels. “We aim to assess their performance in real-world scenarios, evaluate their durability, and optimise their manufacturing process for large-scale production,” said Dr Chu.

“Simultaneously, we are actively engaging with industry partners and potential clients to gather feedback and refine the labels based on specific application requirements.”

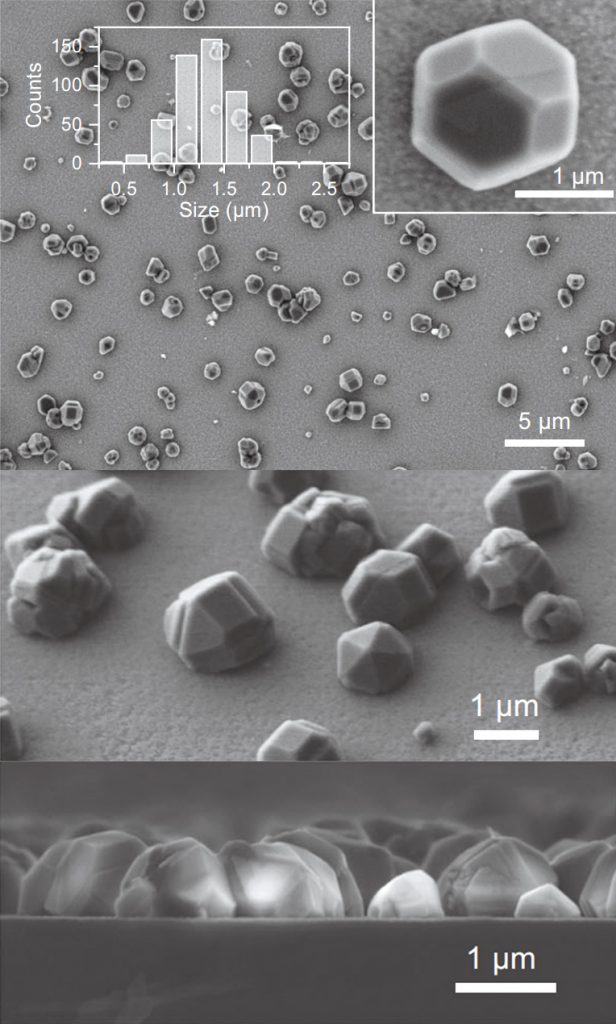

The top view (top), side view (centre) and cross section (bottom) of electron microscopy images of a diamond Physically Unclonable Functions label. The individual diamond microparticles and their spread on the silicon substrate are clearly visible.

Because the diamond microparticles are all different shapes and sizes, when scattered on the silicon substrate, they settle in a unique pattern each time, thereby creating the equivalent of a fingerprint for each label which is impossible to copy.

DR ZHIQIN CHU